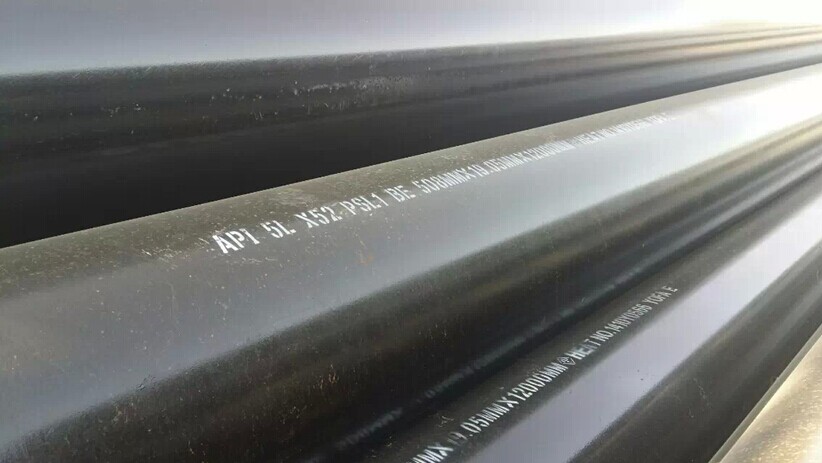

Fluid Transportation Steel Pipe

Grade: PSL1 PSL2

Main material: Q195-235 20#16Mn Q345(B,C) L175-L555(X42-X80), J55, K55, N80

API 5L x52: Min Yield Strength - 52 ksi, Min Elongation: 21%0.16% C, 0.45% Si, 1.65% Mn, 0.02% P, 0.01% S, 0.07% V, 0.05% Nb, 0.04% Ti

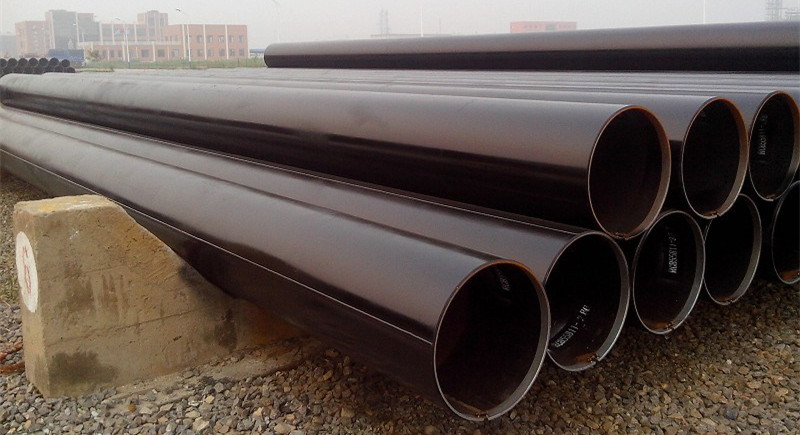

Main Usage:The API 5L specification provides standards for pipe suitable for use in conveying gas, water, and oil in the natural gas and oil industries. The API SPEC 5L covers seamless and welded steel line pipe. It includes plain-end, threaded-end, and belled-end pipe, as well as through-the-flowline (TFL) pipe, and pipe with ends prepared for use with special couplings.

Standard Specification for Line Pipe:Specifications for API 5L adhere to the International Organization for Standardization ISO 3183, standardizing pipeline transportation systems within the materials, equipment and offshore structures for natural gas, petroleum, and petrochemical industries. When authoring the standards, the technical committee recognized that there are two basic Product Specifications Levels (PSL) of technical requirements and therefore developed PSL 1 and PSL 2. PSL 1 is a standard quality for line pipe where PSL 2 contains additional chemical, mechanical properties, and testing requirements.

Grades covered by this specification are A25, A, B and "X" Grades X42, X46, X52, X56, X60, X65, X70, and X80. The two digit number following the "X" indicates the Minimum Yield Strength (in 000's psi) of pipe produced to this grade.

API 5L Steel Pipe Benefits & Applications:

Fluid transportation steel pipe- preferred in long pipelines due to inexpensiveness

Pipeline steel - resistance to crack propogation

Line Pipe / Sour Service Line Pipes

Threeway Steel is known as a professional supplier engaged in manufacturing and distributing a wide range of steel pipe, and our headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in manufacturing and distributing a wide range of steel pipe, and our headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.