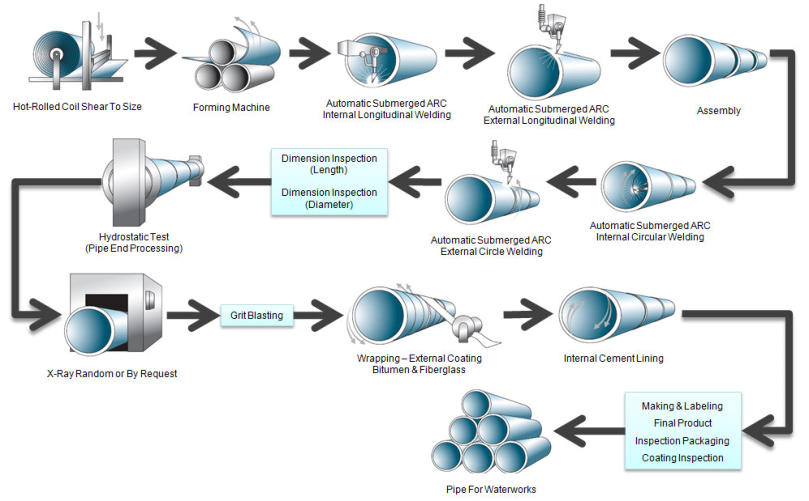

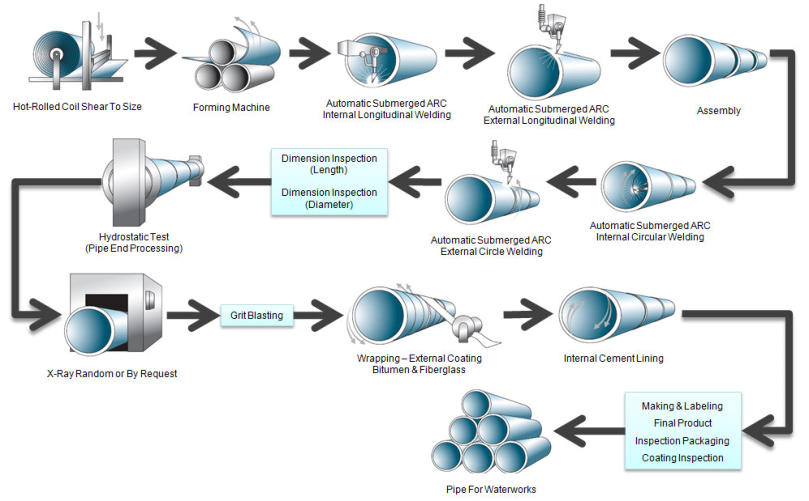

The raw material used in manufacture of Spiral SAW is H.R. Coil. It is continuously formed to require the specific diameter of the pipe, spirally welded at high speed and cut to required length. The following operations are carried out when the material is loaded for making of the pipe.

Entry Line : Here the coils are opened, edge milled to required width and fed to forming stand at uniform speed. This unit also enhances the joining of the tail-end of the out going coil with theleading end of the incoming coil to produce continuous strips. Before initializing new campaign, entry line will be positioned in an angle, called Helical Angle in respect to the normal of forming table center axis.

Forming Stand :The unit performs as the heart of the mill.

Here the strip is formed to required size of the pipe & spirally welded.

Exit Line :The main purpose of exit line is to give proper support to the pipe during forming, cut the pipe to required length and eject it outside.

The pipe is then visually inspected thoroughly, both in & out side, for probable weld defects such as under cut, porosity. If any defects found, it will be rectified as per the approved QAP (Quality Assurance Plan). After this the pipe will be sent to Beveling (Chamfering & Facing) machine for better quality pipe joints during laying works at site. Then the pipes are hydrostatically tested to ensure that there is no leakage from weld joint or parent material.

The pipe will be inspected at different stages of production to ensure the quality of the product. The inspection process consists of Physical / Visual Inspection, Destructive & Non-Destructive Testing & final inspection before sending for dispatch.

Threeway Steel is known as a professional supplier engaged in manufacturing and distributing a wide range of steel pipe, and our headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in manufacturing and distributing a wide range of steel pipe, and our headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.

Threeway Steel is known as a professional supplier engaged in designing, manufacturing and distribution of a wide range of steel products with the headquarter located the central part of China – Hunan and six associated factories throughout China.